Product Highlight: Atlas Copco’s STB Series

When you’re searching for an electric nutrunner, you’ll find there are a lot to choose from, but at Encore Systems, we particularly like Atlas Copco’s STB series.

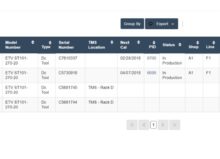

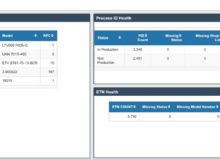

STB nutrunners are battery-powered, provide precise and repeatable control over rundown, and are designed with extensive Industry 4.0-level data collection capabilities. What’s more, their excellent ergonomics reduce fatigue and mistakes, making them a popular choice on the plant floor and in the quality office.

STB nutrunners are available in both pistol-grip and right-angle configurations. The former tops out at 590 in-lbs (799 Nm), while the latter go up to 109 ft-lbs (147 Nm).

Features & Benefits

- Wireless Data Capture: Every model in the STB series transmits rundown data to a central hub with no awkward or unwieldy cables.

- Battery Powered: No power cables mean complete mobility within the workplace. When swapping out the main unit, a second buffer battery within the nutrunner maintains the wireless connection. Plus, the series’ clever design makes it impossible to fit the wrong battery.

- Signal Lights: All models have easy-to-read signal lights for tightening status, batch OK, battery status, communication status, and tool events.

- Ergonomic Design: These nutrunners feature an ergonomic, compact, cable-less design and industry-leading performance ratio weight that prevents injuries, minimizes fatigue, and reduces the risk of mistakes.

- Integrated HMI: This feature, only available in certain models, allows the operator to easily see every detail of the rundown.

- Optional Barcode Reader: The optional barcode reader improves traceability, provides full error-proofing, and ensures higher productivity.

Applications

STB nutrunners can be used in just about any situation requiring quick fastening. However, they are particularly beneficial in two scenarios:

- Where over- or under-tightening risks in-service failure, with possibly serious consequences.

- When the manufacturer needs a record of the torque and possibly the angle applied to the joint.

These situations include tightening of gasketed joints, where under- or over-tightening will result in leaks, and rotating and vibrating machinery, where a fastener could loosen and collapse.

Applications like these are found in:

- Aerospace Assembly: Thermal cycling, combined with vibration, can loosen fasteners in engines and airframe structures. STB series nutrunners provide the accuracy and records to deliver complete confidence in assembly integrity.

- Automotive Manufacturing: From suspension and engine components to assemblies like fuel pumps and injection systems, correct tightness is vital for safety and reliability.

- Medical Device Assembly: Correct torque is essential to avoid premature failure or malfunction of equipment and devices used for patient care. The STB nutrunner captures data that provides the level of traceability needed.

- Chemical Processing: Applying the incorrect torque to a pipe flange or connection risks leaks and possibly hazardous fluids.

- Power Generation: The rotating equipment found in wind turbines and steam-driven power generation places high loads on bolted connections.

Request a Quote Today

Encore Systems specializes in repairing and calibrating DC assembly tools, such as Atlas Copco’s STB series. We follow a stringent ISO-certified process to ensure quality and even offer expedited repair services for emergencies. We also maintain a large inventory of lower-cost recertified models that can be shipped quickly to plants in the United States. All tools we repair and sell are backed by an optional warranty.

Please contact us today if you’re interested in purchasing a recertified STB nutrunner or if you have an existing one that needs to be serviced. You can call (937) 833-4469 to request expedited repairs.