Tool Management Service

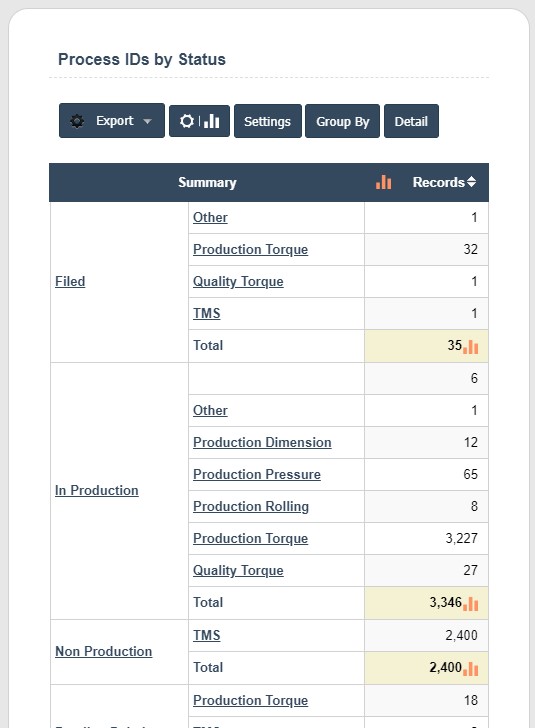

Our custom tool tracking system provides organization for all your torque equipment, including calibration and history and calibration alarms.What Our Custom Tool Management System Can Do for You

Data Input/Tool Management

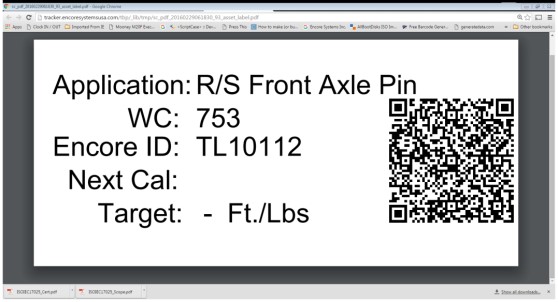

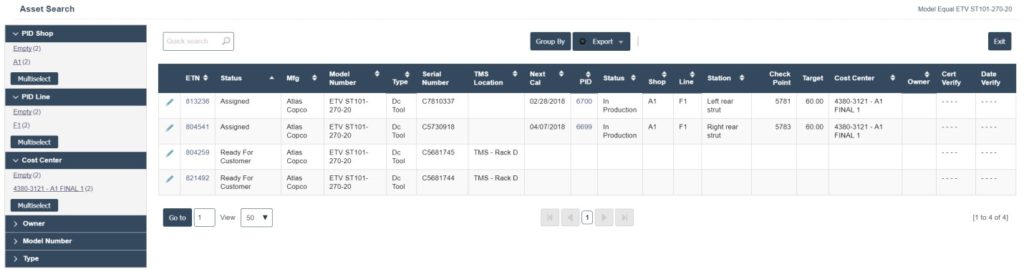

When you add new tools to Encore’s QME system, you can include all the details of that tool. That includes the serial number, manufacturer, part number and type. Having all of this information stored on a web-based tool ensures easier data recovery and sharing capabilities. In addition to recording the details of each tool or piece of equipment, you can also track its applications, performance targets, locations, and current disposition.

Repair Information

Our tool management system will also allow you to track repair data, which will help you make more cost-effective decisions down the road. The repair data could include the total cost of repairs, the number of repairs for each part, the job details of the repair, and when the repair took place.

Job Documentation

Beyond simply tracking the specifics of your tools, you can also track any job details, including the type of job that was done, whether calibration, repair, or preventative maintenance.

Calibration Data

You can also track your calibration data when you use our software. This includes your previous calibrations with our company or calibrations that you’ve done on your own. You can even upload the calibration certificate for ISO compliance.

Preventative Maintenance Due Dates

When do your tools need to come offline for preventative maintenance? If you’ve had trouble remembering important maintenance dates, use our tool management software. When you have PM work done, you can record it in the software and set reminders, like when your torque equipment needs to be calibrated next.

Customized to Meet Your Needs

At Encore Systems, we understand that not every industry is the same. We customize our software to meet your needs. We take into account the conditions of your facility, the demands on your tools, and the expected lifespan and needs of specific models. You can also generate custom reports based on repair and calibration data, offline spares, online tools, and more.

Why You Should Work With Encore Systems

Based in Brookville, OH, Encore Systems has been a trusted source in the U.S. for emergency torque repairs, calibrations, and more. We’re known for our state-of-the-art technology (SolidWorks, FDM modeling, RTV molding, and CNC machining), as well as our specialized obsolete tool repair services. In addition to our stellar reputation for quality, the benefits of working with us include:

- ISO-Certified to Better Help You Stay ISO Compliant

- Quick Response Time

- Significant Savings

- Free Evaluations & Software Demonstrations

- Technical Support

Have Questions? Contact Encore Systems Today

Implement Encore’s tool management system into your workplace and enjoy a more organized inventory, certified and verified calibrations, accurate scheduling of PMs and calibrations, and real-time reporting. Whether you need help with one tool or thousands, you can trust our software for accuracy and reliability. Please fill out our online form to learn more about our tool management solutions or schedule a demonstration.We Service Top Brands

We are not affiliated, associated, or in any way officially connected to these OEM's